The Open Architecture!

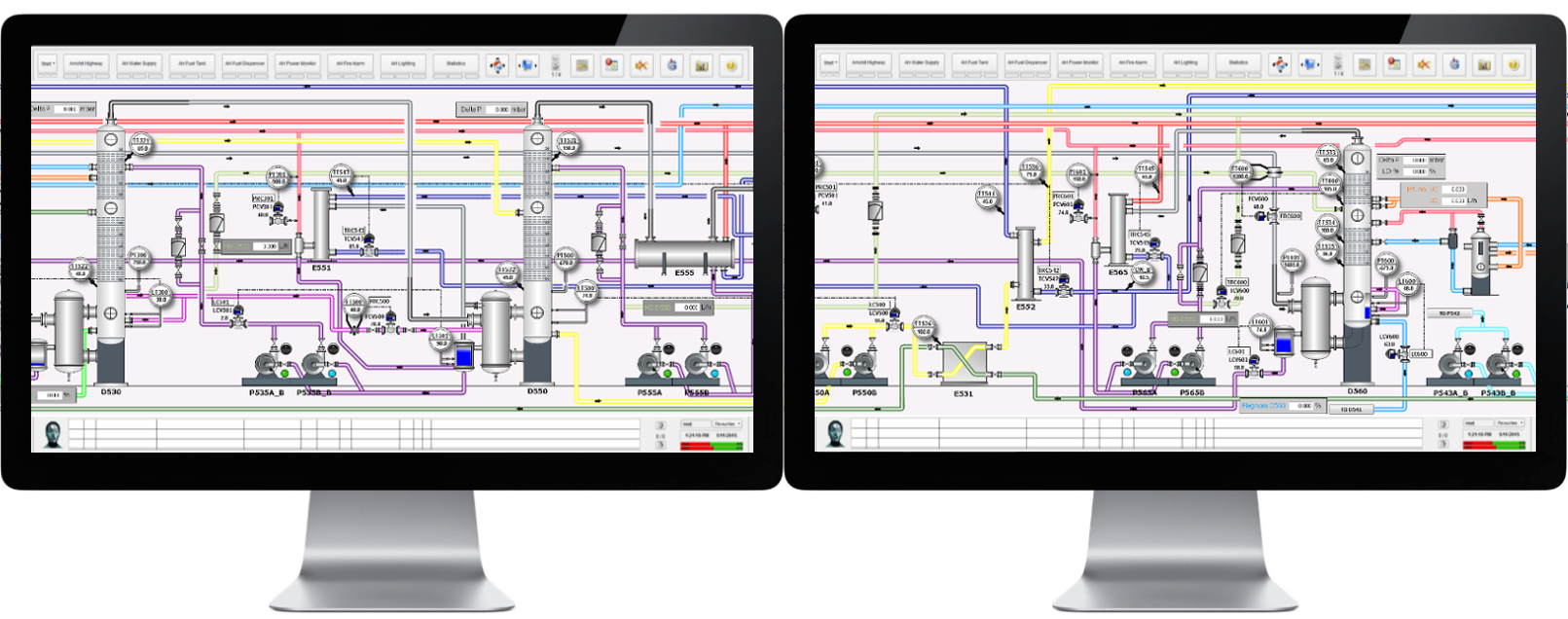

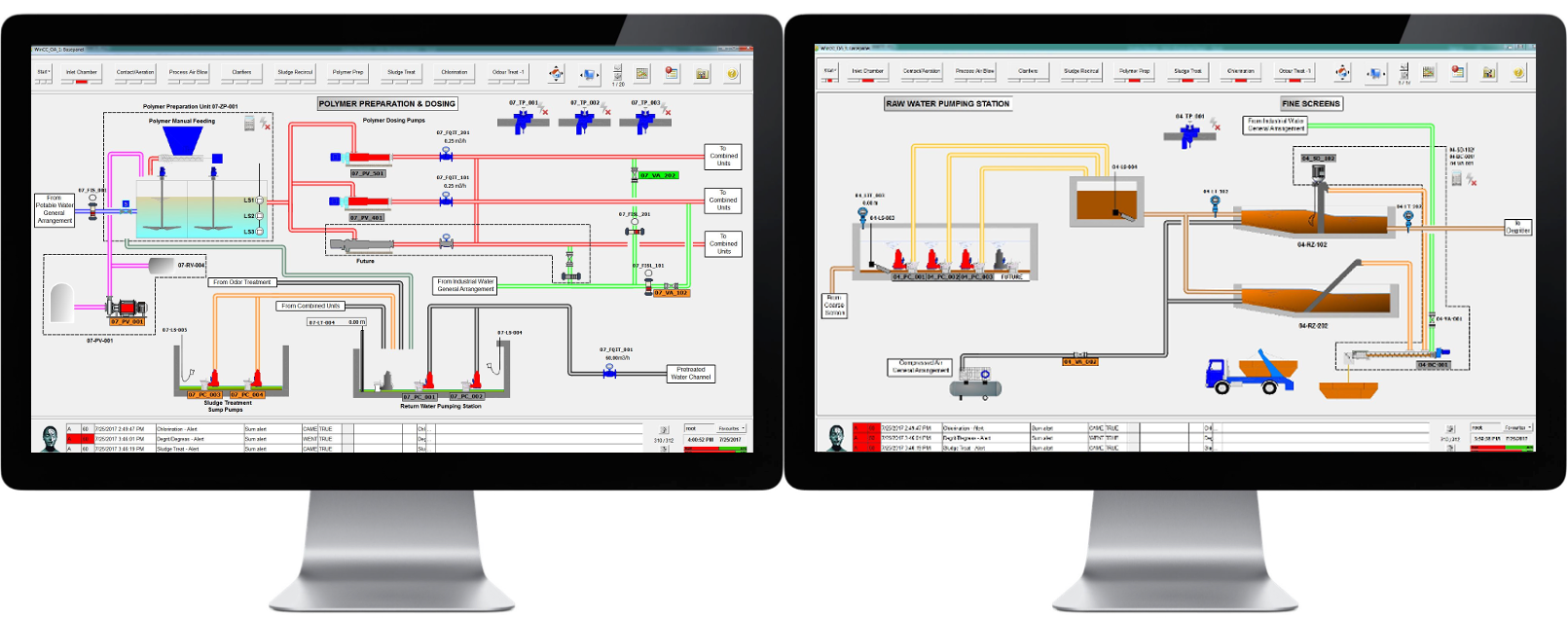

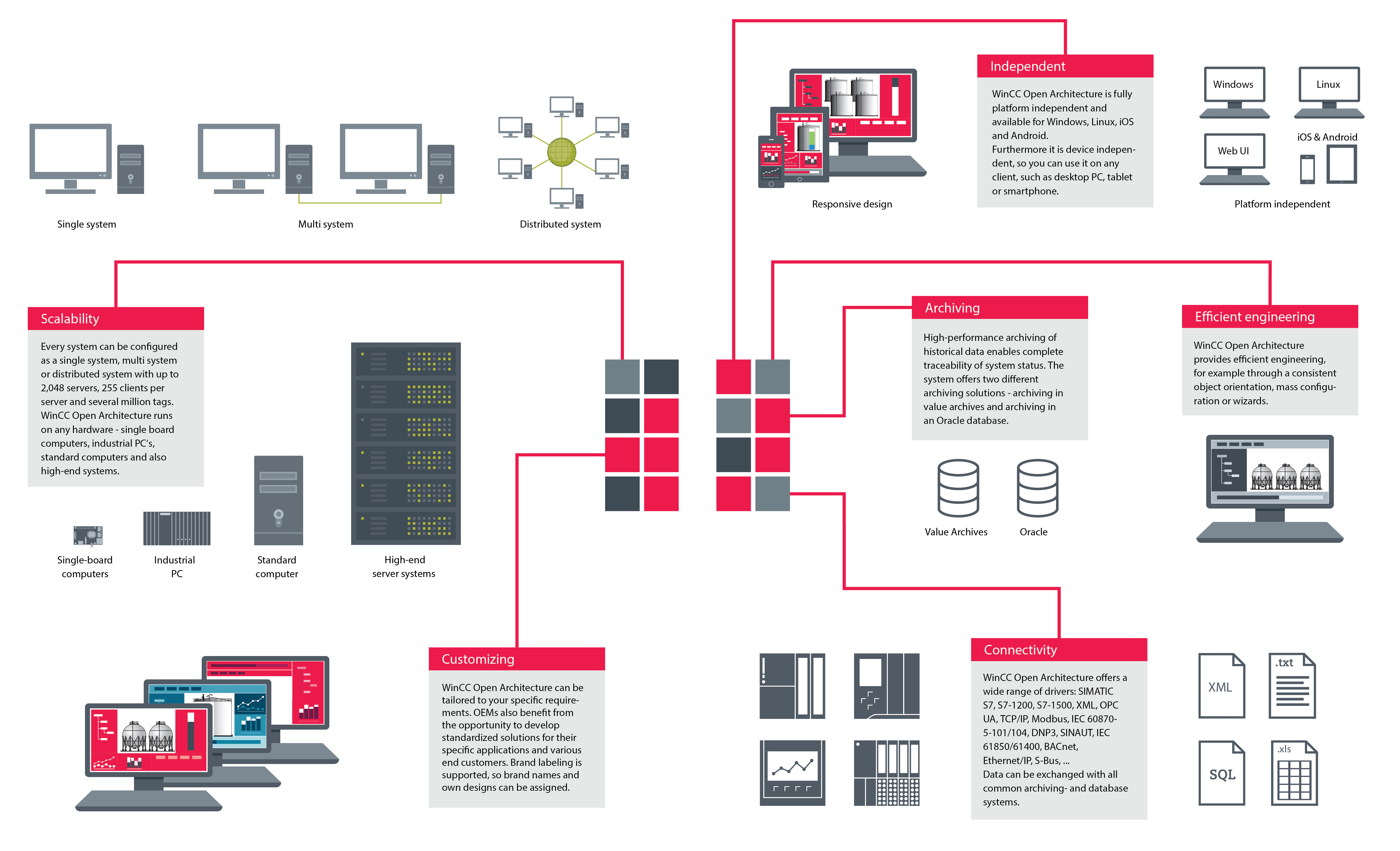

SIMATIC WinCC Open Architecture is a SCADA system for visualizing and operating of processes, production flows, machines and plants in all lines of business. Distributed systems enable any number of stand-alone systems, from 2 to 2048, to be linked via a network.

Each subsystem can be configured either as a single-user or multi-user system, redundant or not, in each case. SIMATIC WinCC Open Architecture relies consistently on object orientation for process images and the database structure.

SCALABALE USER EXPERIENCE

Modern systems are subject to constant change and new demands. SIMATIC WinCC Open Architecture is adaptable and grows with the necessary extensions, without coming up against limits. SIMATIC WinCC Open Architecture scales to requirements - from the small single-site system for machine operation to the networked, redundant high-end system.

WORLDWIDE EXPERTISE

As a member of the worldwide network of certified WinCC OA Partners and system integrators, AutomatiX realizes customer projects in the region, having complete support directly from Siemens and in the same time benefting from the huge experience Siemens and WinCC OA partners have worldwide

OPEN

Empower your platform independence with software that supports virtualization and available for Windows, Linux, Solaris, iOS, and Android operating systems.

SCALABLE

From the automation level up to management use. WinCC OA is a system without limits and adaptable to grow with the necessary extensions as needed

EFFICIENT

Use single board computers up to large complex systems. WinCC OA's event based system provides twice the functionality with half the hardware requirement.

INNOVATIVE

WinCC OA employs cutting-edge development concepts. End-to-end object orientation sets news standards for industrial information software.

SCADA system with smart analysis function

The optional SmartSCADA supports analysis of installations through key performance indicators (KPI) along with subsequent optimization using statistical techniques.

Data mining is used to select relevant data from large data volumes whereby relations and dependencies between various process values are recognized and used for further classification. During the classification of the selected data results are linked, conditions automatically recognized, and named by the user. Such analyzed data is used for drafting statistical models. These models can then be used for optimizing the installation, for instance to run efficient cause analysis. This can be done using both historical and real-time data.

SmartSCADA is sector independent and can be deployed for manifold applications including wind power installations, energy supply systems or large production facilities.

With the SmartSCADA option, WinCC OA can be used for root cause analysis, preemptive maintenance, condition monitoring, and much more.

FIELDS OF EXPERTISE

UNDER THE PARTNERSHIP OF SIEMENS SIMATIC WINCC OA / ETM

Oil & Gas - Terminals Automation

The Terminal automation system constitues a dediatced section developed by AutomatiX and featuring Siemens as an automation backbone and MTS USA as high accuracy level sensor based on magnetostrictive technology which enables the cilent to obtain real-time accurate and reliable reflection of the level of the product, in addition to the temperature at several point along the depth of the tank. This system is integrated in numerous oil and gas terminals locally and abroad with magnificient results contributing in minimizing the technical and non-technical losses.

Telecom Infrastructure SCADA Systems

As more and more people rely on mobile communications in their daily lives, the pressure on telecom infrastructure is increased. We want telecom base stations to achieve higher performance while decreasing operational costs. This can be a real challenge, especially in rural and scarcely populated areas where we might lack a well-developed power grid and the nearest service technician is miles away.

There are many actions that can be taken to improve operations and reduce costs, for example using newer energy-efficient equipment and integrated power management systems to use power more efficiently. These actions may work well when a new site is being built, but the investment may be harder to justify on existing sites as it requires replacing existing, well-functioning equipment with new.

Our Solution, built totally on SIEMENS platform will improve operations and reduce operating costs on existing sites.

This is achieved by understanding when, how and if equipment is operating, we are able to make better decisions regarding site maintenance and take actions when necessary.

Pharmaceutical Solutions

SIMATIC WinCC abd WiniCC OA are our modular SCADA System. Our System is ideally suitable for all process requirements and covers all aspects of the pharmaceutical industry - from the operation of individual machines to complete plant operation. The innovative visualization software is characterized by open interfaces and a high degree of flexibility and scalability. SIMATIC WinCC makes it possible to implement a comprehensive operator control solution with uniform audit trail and central message functions. The modular structure allows close linkup of the production environment to the MES system on the basis of SIMATIC IT as well as to the business management systems. This powerful system enables the user to optimize his manufacturing performance and supply chain and make quality into an integral component of his processes.

For machine-oriented operator control and visualization, SIMATIC WinCC offers extensive flexible functions for the documentation of all processes. The innovative enginbeering software inetracts harmoniously with PC systems as well as with SIMATIC Panels. This makes it possible to make compact touch panels ready for configuration by the operator on the machine level. The touch screen solution is connected to a highly effective client/server system and a PC visualization system, meeting the relevant GMP/FDA requirements.

Go beyond... IEC 61850 / 61400

SIEMENS Open SCADA for seamless connection to protection relays!

Connection of IEC 61850 and IEC 61400 devices such as SIEMENS, ABB, Schnieder and more... including browsing the entire system.

Siemens is the global market leader in this area. For you, that means: You benefit from the experience of projects for more than 1000 substations and 140000 protection devices implemented in accordance with the IEC 61850 communication standard by the end of 2010. Siemens offers you IEC 61850 technology that is certified as Class A by the independent testing laboratory KEMA. Future-proof investment due to convincing migration concepts: SIPROTEC 4 protection devices manufactured since 1998 can be upgraded to make them IEC 61850-compatible without any problem. The solutions from the SICAM 1703 and SICAM PAS product lines offer you flexible configurations for seamlessly integrating the latest IEC 61850 concepts into existing substations.

While reading the brochure "Application examples" under downloads, discover the diverse efficiency potential of energy automation with the IEC 61850 worldwide communication standard.