Explosion Protection

Pepperl+Fuchs is a leading supplier of automation equipment for a wide range of industries and has been associated with safety in hazardous areas for decades. Our deep expertise enables us to offer a complete range of automation solutions for the process automation industry.

The product portfolio includes intrinsic safety isolators, Zener barriers, signal conditioners, fieldbus technology, Remote I/O, HART interfaces, level measurement, purge & pressurization systems, Human Machine Interfaces (HMI) for hazardous environments, custom cabinets, and junction boxes.

We provide process industry companies all over the world with proven components and tailor-made solutions for a diverse range of applications. The branches that we cover include the oil and gas industry, petrochemical, chemical industry, pharmaceutical industry, as well as wastewater treatment plants, and power technology.

Intrinsic Safety Barriers

Intrinsic safety barriers from Pepperl+Fuchs limit the energy that is supplied to a circuit and protect hazardous areas from excess energy. By limiting energy to a safe level, intrinsically safe circuits prevent the ignition of potentially explosive atmospheres. This simplifies maintenance and repair of Ex i circuits.

Pepperl+Fuchs offers a variety of intrinsic safety barriers for different requirements. Select between isolated barriers and Zener barriers that ensure safe signal transmission in hazardous areas.

Signal Conditioners

Signal conditioners protect signal transfer between field devices in safe areas and control systems by galvanic isolation of the loop.

Particularly in case of long transmission paths, signal conditioners avoid compensating currents which may occur from ground loops. Signal conditioners also offer effective protection against electromagnetic disturbance or dangerous over voltages on the signal loops.

Depending on the type, signal conditioners offer additional features like limit switching, transformation from field in standard signals, as well as splitting of signals, which means doubling the input signal.

FieldConnex Fieldbus Infrastructure

FieldConnex® - Always the Right Choice

FOUNDATION fieldbus H1 and PROFIBUS PA link field instrumentation to any process plant. Fieldbus provides seamless data communication between the plant and control system while supplying power to all field devices.

Fieldbus topologies fit the demands of modern process industries. The High-Power Trunk approach provides plenty of energy and the flexibility you expect for your process. Make the High-Power Trunk your choice of fieldbus technology for FOUNDATION fieldbus H1 and PROFIBUS PA

Robust power supplies and reliable fieldbus installation technology

Advanced Diagnostics for comprehensive performance monitoring

Well-tuned protection concepts for any explosion hazardous area

Safety is not an issue and stability is ensured.

You can even get the intrinsically safe High-Power Trunk for Zone 1 with DART Fieldbus.

FieldConnex is fieldbus connectivity. From power supplies to fieldbus terminators to fieldbus barriers – let our experience deliver reliable, valuable, and cost-effective products to you. Long component service life protects your investment and increases the efficiency of your application.

Remote I/O Systems

Modular remote I/O systems transmit process data from safe or explosion hazardous areas by connecting binary and analog sensors and actors to the control system via a bus interface. Remote I/O is the right choice when you want to put I/O modules close to the field devices. Due to the reduced wiring effort, you not only save cables, but also time, money, and work effort. Hence, remote I/O field units can be installed in a decentralized location inside hazardous areas while you easily control and monitor sensors and actors from the control room.

You can connect 4 mA … 20 mA devices to remote I/O, including water flow transmitters, valve positioners, pressure transducers, or temperature transmitters. Devices such as thermocouples, resistance temperature detectors (RTDs), mechanical contacts, and visual or audible alarms may also be connected.

Our remote I/O systems are compatible with network protocols like:

PROFIBUS DP

MODBUS RTU

MODBUS TCP/IP

FOUNDATION Fieldbus H1

HART Interface Solutions

HART Interface Solutions from Pepperl+Fuchs consist of two HART Multiplexer Systems for multiple signal loops and a HART Loop Converter for single loop applications. The Multiplexer is used to connect HART field devices to Asset Management Systems like AMS™ Suite: Intelligent Device Manager from Emerson Process Management. At the heart of HART Interface Solution (HIS), the HART Multiplexer acts like a gateway device, routing communications between the maintenance workstation PC and the HART field devices. It interrogates each HART device, retrieves device information, and stores it in an internal database. This information is made available by the AMS Device Manager or PACTware. The HART Multiplexer also acts as a message coordinator for communication between the maintenance workstation PC and the HART devices. For a single loop solution, the HART Loop Converter allows access to all process variables provided by a field device and transfers them to conventional 4...20 mA loop. This enables it to make use of the hidden measurements done by many field devices and feed them to conventional DCS Systems.

Surge Arrestors

In process engineering plants such as refineries with exposed building parts or extensive water management systems, surge events can cause disastrous consequences: from damage or destruction of expensive components and machines to breakdown of complete automation systems—not including risks to personnel.

Besides these dangerous risks to people and environment, overvoltages are still one of the most common causes of damage in electrical plant engineering. They primarily occur due to lightning strikes or switching operations, but also due to the following causes:

Electrostatic discharge

Brush fire of large electric machines

Fluctuations in power supply

Ground faults / short circuits

Triggering fuses

Parallel installation of energy and information technology control systems

Pepperl+Fuchs‘ surge protection modules reliably divert surges and currents to ground and protect people and machines against possible negative consequences. Our product range provides you with powerful surge protection solutions for various applications. Find devices for signal line protection, supply line protection, fieldbus, and wireless solutions.

Wireless Solutions

WirelessHART networks for process automation

Wireless communication quickly gains relevance in automation applications. For process automation, it is not the amount of data that poses challenges, but the distances to be bridged. Whenever the plant architecture does not allow conventional wiring, values are only accessible through frequent visits to the field.

WirelessHART offers a cost efficient solution. Measured values become available on a regular basis, which leads to increased quality and more economical operation of process plants.

In a WirelessHART based network, every participating device simultaneously works as a signal source and a repeater. Through the routing of the individual signals across the entire network, a wide network structure becomes possible.

WirelessHART products from Pepperl+Fuchs

Pepperl+Fuchs offers several modules to connect sensors to a control system or asset management system with a wireless network. These WirelessHART products support the installation of field devices from different manufacturers without the need for additional wiring effort and costs. A reliable, interference-free communication is established with the following components.

Industrial Monitors+HMI Solutions

VisuNet portfolio

No matter if you want to connect to a PLC, run a local application on an industrial PC in the hazardous area, or you want to connect to a host system in the safe area: Pepperl+Fuchs provides a fitting solution. Choose a product from our VisuNet portfolio according to your individual needs.

Electrical Explosion Protection Equipment

Pepperl+Fuchs offers a broad portfolio of electrical equipment and solutions for installation and control of machinery and electrical networks in harsh environments and explosion-hazardous areas.

Various types of protection and enclosure variants along with a high level of flexibility allow the design of the most efficient control and distribution solutions for any application and industrial environment.

Experienced project engineers at the Pepperl+Fuchs Solution Engineering Centers—located worldwide—will support the user to find the most efficient solution for his specific requirements.

Purge+Pressurization Systems

Bebco EPS® purge and pressurization by Pepperl+Fuchs is a household name in the process automation industry. As the leaders in Purging Technology®, we manufacture innovative solutions that are remarkably simple to use and will easily handle just about any application.

With Pepperl+Fuchs' Bebco EPS purging and pressurization, you get:

State-of-the-art solutions based on more than 20 years of experience – a family of automatic purge and pressurization systems that make hazardous location protection easy

Technical support – anywhere in the world

Purge and pressurization systems designed according to ATEX direction 94/9/EG, NFPA 496, and ISA 12.4 standards

Easy integration – compact, low-profile designs that can be internally or externally mounted

Automatic temperature and leakage control and alarming

User interface with programming to meet most users' demands

Pepperl+Fuchs offers a full range of purge and pressurization equipment to meet the needs of your application. Another benefit of purging and pressurization is use of the standard Type 4/12 enclosure as the protected enclosure. This saves money, weight, and space over explosion-proof methods. Need a certified solution? The Pepperl+Fuchs Systems and Solutions group can also design custom, certified enclosure solutions.

Power Supplies

Power supplies for hazardous areas

Pepperl+Fuchs understands the need for reliable power in hazardous areas. Our power supplies meet the most demanding requirements for today's process control applications, and help to enhance system integrity. Our power supplies are well suited for emergency shut down and mission critical applications to fieldbus and analog networks including HART communication.

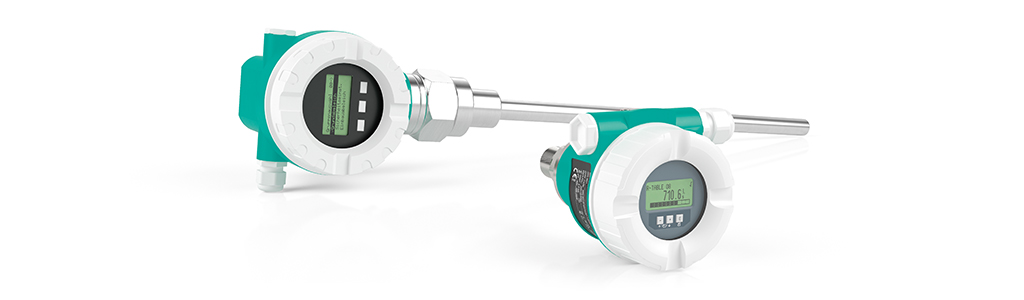

Intrinsically Safe Mobile Devices

Today, level measurement technology is the basis for management and process control in the chemical, petrochemical, environmental and other related industries.

Our comprehensive program enables us to help you solve your particular measurement and control problems and to detect the precise level of any medium, under a wide range of conditions.

Industrial Sensors

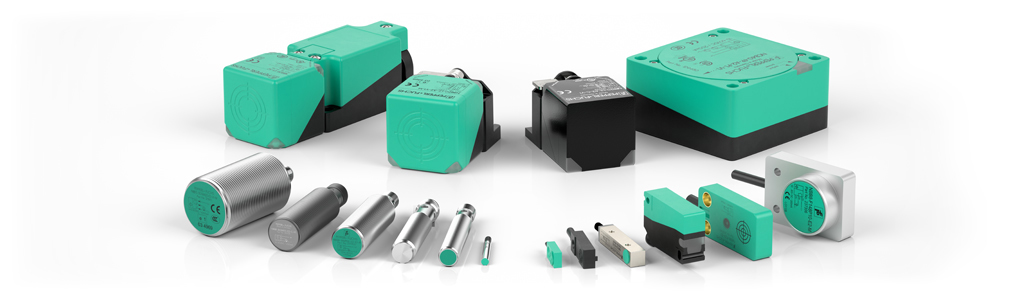

For decades, Pepperl+Fuchs has been developing and distributing industrial sensors and sensor systems with the highest quality standards for use in automation technology. The diverse product portfolio offers sensors for standard applications as well as customized solutions. In close cooperation with our experts, you receive the ideal sensor system for your specific requirements!

Our product portfolio of industrial sensors for factory automation is characterized by a high degree of innovation. It consists of inductive, photoelectric, capacitive, magnetic, and ultrasonic sensors. Additionally, we offer you powerful components such as rotary encoders, positioning and identification systems (RFID, Data Matrix, Barcode), AS-Interface as well as suitable accessories. Industrial vision systems and vision sensors round off the comprehensive product range.

State-of-the-art technologies and a global sales and production network make Pepperl+Fuchs the ideal partner for a wide variety of industries in the global market. These include branches like mechanical engineering, automotive industry, material handling, packaging, print and paper industry, doors, gates and elevator construction, process equipment, mobile equipment, and renewable energy.

Proximity Sensors

Inductive Sensors

Inductive proximity sensors are the preferred choice for the majority of applications requiring accurate, non-contact detection of metallic objects in machinery or automation equipment. As a pioneer and market leader, Pepperl+Fuchs offers innovative, high quality inductive sensors to meet the needs of the worldwide automation and process control markets. Our experience, flexibility and customer focus continues to allow us to offer custom designed solutions for the most unique and demanding applications.

Standard Inductive Sensor Product features:

Smooth or threaded stainless housings

Polarity reversal and short-circuit protected

LED status indication

Connection styles include M8, M12 or terminal connection models

Models with PVC, PUR or silicon cable

Outputs in 2-, 3-, 4-wire DC, AC, NAMUR, and AS-Interface versions

Application Specific Inductive Sensor features:

Analog output models with 4-20 mA output signal

Integrated speed monitor with up to 100 Hz operation

Pressure resistant cylinder sensors for up to 500 bar

Sensors approved for gas and dust Ex zones

Models with stainless steel sensing face

Protective class of up to IP68/ IP69k (submersible/ high pressure water jet resistant)

Weld resistant designs with PTFE-coated surface

Reduction factor of 1, all metals sensed at same distance

Exclusive ferrous and non-ferrous detection models

Safety function sensors

Extended temperature range: -40 °C up to +250 °C

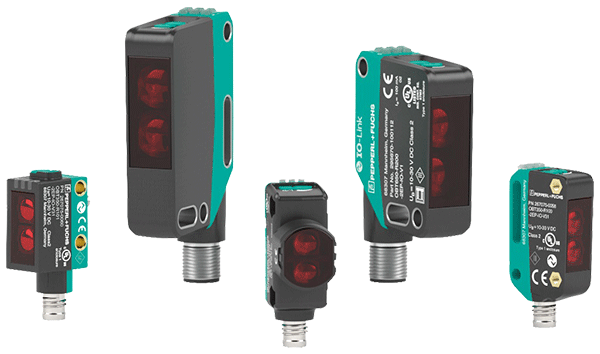

Photoelectric Sensors

Thru-Beam Sensors

The emitter and receiver on thru-beam sensors are aligned opposite one another. The advantage of this is that the light reaches the receiver directly and long detection ranges and high excess gain can therefore be achieved. These sensors are capable of reliably detecting almost any object. The angle of incidence, surface characteristics, color of the object, etc., are irrelevant and do not influence the functional reliability of the sensor.

Retroreflective Sensors

The emitter and receiver are aligned in a housing such that the retroreflective sensors are easy to install. Simply position a reflector on the opposite side and align the sensor with it. The standard version featuring a polarization filter combines the installation benefits offered by the retroreflective system with the reliable detection, even of reflective objects, at long detection ranges. The retroreflective sensors for clear object detection are ideal for reliably detecting transparent objects.

Switching Sensors with Measurement Core Technology

Switching sensors with measurement core technology are based the Multi Pixel Technology (MPT) developed by Pepperl+Fuchs. Thus, multiple operating modes and switching points are easily set up in a single triangulation sensor. These photoelectric sensors can be configured as background suppression sensors, background evaluation sensors, and in window operation mode. Additionally, the sensors are equipped with a standard IO-Link interface which enables users to easily integrate them into versatile applications.

Fiber Optic Sensors

Fiber optic sensors and cables are the perfect solution for applications where the direct mounting of sensors is not possible due to space restrictions, temperature extremes, and so on. Small fiber optic beams are ideal for detecting tiny objects.

Slot and Slot Grid Sensors

With a fast response time, the devices are ideal for detecting tiny objects from long distances. They are frequently used to detect objects on vibrating and oscillating conveyors. Slot grid sensors handle challenging counting and monitoring tasks such as detecting non-guided objects in free fall.

Contrast Sensors and Color Sensors

In the automation of packaging and printing processes, the reliable detection of print and color marks plays a key role in coordinating the various processing steps. Photoelectric contrast sensors are specially designed for such detection tasks.

Light Grids

Light grids are ideal for applications where wider areas need to be monitored. Light grids are much easier to mount, install, and align and are therefore preferred to multiple individual photoelectric sensors. Application areas range from controlling the width, height, and profile of pallets in material handling facilities to detecting position-independent objects, controlling overlap on larger conveyed goods, and monitoring elevator doors.

Distance Sensors

Even the smallest model is suitable for a wide range of measuring and positioning tasks. It operates using laser triangulation and an analog output. All other sensors from the VDM series use Pulse Ranging Technology, offer long sensing ranges, and achieve extremely accurate measurement results. PRT uses high-intensity light pulses to provide a high degree of operating reliability, even under difficult ambient conditions with exposure to ambient light and dust.

Optical Data Couplers

The optical data couplers were designed to establish wireless communication with stock feeders, industrial trucks, automated transportation systems, overhead conveyors and docking stations. Mechanical and problematic RF- and Wi-Fi-based transmissions are avoided as a result. Devices with a variety of operating ranges and transfer rates are available.

Photoelectric Safety Sensors

Personnel protection is becoming increasingly important in automated processes. Wherever machines perform high-risk movements, the relevant health and safety regulations must be observed. Even if the operator is momentarily distracted, shearing, crushing, and impact injuries must be prevented.

Special Sensors

Pepperl+Fuchs developed a number of industry-specific special devices for applications that are functionally not covered by the standard program. The application-specific sensors offer completely new possibilities in optical sensor technology for the user searching for the “right" solution.

Sensors for Automated Accesses and Entrances

Nowadays, it is hard to imagine life without escalators, automatic doors, gates, barriers, and elevators. As if by magic, they open automatically, detect obstacles, and appear to react quite naturally to approaching people and objects.

Photoelectric Sensor Accessories

An extensive selection of accessories complements our photoelectric sensors product line, with application-specific fiber optic cables, mounting brackets, and a broad range of reflectors.

Industrial Vision

Image processing is one of the most crucial and challenging sensor technologies of the future. Until recently, integrating vision sensors into practical applications was difficult and extremely expensive. Today, vision sensors can be implemented in a wide variety of industries and applications, offering cost advantages over standard solutions in difficult sensing environments.

The available devices and systems range from barcode imagers to vision sensors and system solutions that are adapted to the application requirements. The complexity of the solution and the cost of integration vary with each use. Each technology has advantages that are best suited for the application at hand.

As one of the few suppliers of industrial vision systems, we can accommodate a wide variety of image processing requirements for machine builders as well as for unique system solutions in plant engineering. We offer integrated vision sensor solutions that range from freely programmable devices to user-specific, custom-designed devices.For individual systems with demanding requirements, we provide customer-specific system solutions through our subsidiary, VMT GmbH. Our partnership with VMT enables Pepperl+Fuchs to offer the whole range of industrial image processing from vision sensors via smart cameras to a complete system.

With more than 15 years of experience in the field of image processing, the image processing specialists at VMT work together with our customers on their application requirements to provide turnkey solutions for the field of robot vision, 2-D and 3-D robot guidance, path correction, and machine vision. Other vision sensor principles, such as the multi-camera system for error proofing assembled parts, are also impressively proving their efficiency.

Ultrasonic Sensors

In industrial applications, ultrasonic sensors are characterized by their reliability and outstanding versatility. Ultrasonic sensors can be used to solve even the most complex tasks involving object detection or level measurement with millimetre precision, because their measuring method works reliably under almost all conditions.

No other measuring method can be successfully put to use on such a wide scale and in so many different applications. The devices are extremely robust, making them suitable for even the toughest conditions. The sensor surface cleans itself through vibration, and that is not the only reason why the sensor is insensitive to dirt. The physical principle—the propagation of sound—works, with a few exceptions, in practically any environment.

The measuring method employed by ultrasonic sensors has been viewed as an excessively complex technology, and only used as a “last resort” ... as a solution for particularly difficult applications. Those times have long since passed!

Ultrasonic sensors have proven their reliability and endurance in virtually all industrial sectors.

Rotary Encoders

Rotary encoders can be used in all applications that require monitoring rotation rate, speed, acceleration and direction. These sensors can be utilized in many applications found in mechanical engineering, the conveyor industry, material handling and the packaging industry. You are certain to find a suitable rotary encoder for your application from our broad product offering.

In automation, rotary encoders are used as sensors for angle, position, speed and acceleration. Linear motion can also be measured through the use of spindles, gear racks, measuring wheels or cable pulls.

Rotary encoders convert a mechanical input into electrical signals, which can be processed by counters, tachometers, programmable logic controllers and industrial PCs.

Positioning Systems

Pepperl+Fuchs utilizes different technologies to provide industrial positioning systems for virtually any positioning task. Our product range includes:

Inductive Positioning Systems (PMI)

Distance Measurement Sensors

Position Encoding System (WCS)

Data Matrix Positioning System (PXV, safePXV)

Position Guided Vision (PGV, safePGV)

Electronic CAM-Switch Controller (PAX)

Inclination and Acceleration Sensors

Whether leveling cranes, monitoring front-loader tilt, or controlling elevators—there are many applications for Pepperl+Fuchs’ inclination and acceleration sensors. They ensure precise measurements, even in harsh conditions. An innovative, two-piece mounting concept makes the F99 series extremely robust: a rugged metal mounting bracket provides the sensor module with impact protection and enables quick and easy replacement of the sensor module if needed. Once installed, the bracket can stay in place without need for new adjustment or calibration. With its corrosion-resistant aluminum housing, the one-piece F199 inclination sensor is just as robust and measures inclination from 0 to 360° with ±0.15° accuracy.

Our inclination and acceleration portfolio offers sensors for each of your needs.

Industrial Communication

Fully Networked Communication Ensures Efficient Processes

It is hard to image a time without reliable data flow and transparent communication regarding all production processes. The main objective of industrial communication is to connect all sections of a plant in a single networked system, from the management level right down to the field level. After all, using end-to-end, high-performance data networks increases the availability and efficiency of machines and plants. Pepperl+Fuchs sensors and field devices can be flexibly integrated into existing systems and provide transparent communication and increased productivity.

Today, industrial network communication also allows all business units to be integrated, making it a central component for the availability of data in the Industrial Internet of Things. To enable the reliable and efficient transmission of large quantities of data across all levels, Pepperl+Fuchs offers high-performance, intelligent components—including a full range of AS-Interface system components, a large selection of industrial Ethernet devices, Ethernet IO modules, various IO-Link devices, IO-Link masters, and interfaces.

Identification Systems

Keep Material Flows under Control

With many years of experience in industrial sensor technology and factory automation, Pepperl+Fuchs is your specialist for identification systems. Identification systems from Pepperl+Fuchs enable more cost-effective information capture in production and logistics, as well as enhanced information quality. You will always be up to date on complete inventories, and will benefit from comprehensive tracking and tracing features. In addition, you can improve controlling material flows. And since you have accurate process data, you can continuously improve processes, setting new standards in terms of delivery and inventory management.

Displays and Signal Processing

Sensors used in the automation industry transmit a wide range of digital and analog signals. In many counting and control processes, these signals need to be clearly displayed, monitored, or processed. To help you find the perfect solution for such applications, we offer a wide range of counters, process displays, signal converters, and switch amplifiers that are all optimized for use with our sensors. The user-friendliness and durability of our products is always a priority at Pepperl+Fuchs.

Connectivity

Cables, connectors, and splitters for industrial automation

Automation is our world. However varied automation applications may be, requirements placed on connection technology are just as complex. With the connectivity product portfolio, Pepperl+Fuchs offers a fully integrated solution where sensors and connection technology form a perfect match.

This portfolio ranges from sensor cables to field connectors, junction blocks, sensor-actuator splitters, sensor-actuator receptacles, and data connectors. Whether you are at home in mechanical engineering, welding, material handling, mobile applications, or in process industry – by providing you with sensors and the corresponding connection components from a single source, we boost your productivity and increase the availability of your machines and plants.

Electrical and mechanical system components

.jpg)

Pepperl+Fuchs offers many types of accessories for mounting and connecting all sensor types. These accessories not only save time during initial installation – they also save time and labor when sensors have to be serviced or replaced. And when demanding ambient conditions are present, the right accessory from Pepperl+Fuchs can also significantly increase the operating life of your sensor components.

At Pepperl+Fuchs, you’ll find everything you need for your sensor systems:

Plug connectors

Cordsets

Mounting accessories

Multi-port junction boxes

Reflectors…and more